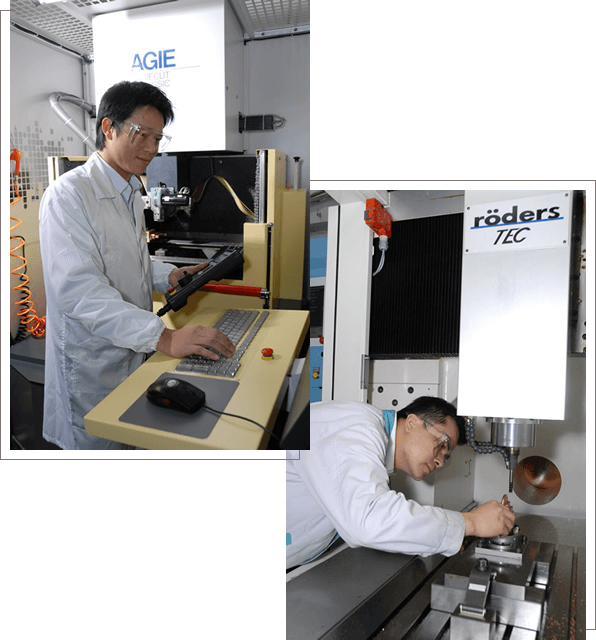

Tooling is the heart and soul of Goodway and also the foundation of every product. Goodway was established 40 years ago as a toolmaker exclusively but has since evolved into a high-tech plastic parts manufacturer. Over these 40 years, we have developed our tooling capabilities significantly by investing heavily in advanced imported tooling equipment and tools from Roders, Agie Charmilles, Makino, Fanuc, Erowa, and more. We have also created our own system to control the progress and quality of molds. However, the key to building a good mold lies in having the right technicians for tooling design, coordination, programming, mold flow analysis, assembly, polishing, and more.

Through our sustained efforts and passion for tooling, we have diversified our expertise to encompass various types of tools for high precision, 2K, 3K, over-molding, insert molding, multi-movements, inner threads, pin core pulling, vacuum tooling, compression silicone, liquid silicone LSR, laser texturing, and even metal injection molding (MIM).

Through our sustained efforts and passion for tooling, we have diversified our expertise to encompass various types of tools for high precision, 2K, 3K, over-molding, insert molding, multi-movements, inner threads, pin core pulling, vacuum tooling, compression silicone, liquid silicone LSR, laser texturing, and even metal injection molding (MIM).

Developed and Hosting by: Topcat Teamwork