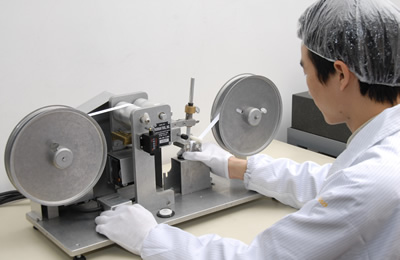

We always work hard to ensure that the plastic components manufactured by Goodway are of the highest standard. We strive to search for new innovations in quality procedures and tools to ensure that these stringent standards are met. We have many quality inspection machines that can detect defects such as temperature shock, environmental aging, MFI, 3D scanning moisture analysis, and more during manufacturing. This helps eliminate possible defects and reduces waste.

Having its own professional and experienced quality control team with a stringent set of procedures ensures the highest possible quality. Our quality control staff works closely with each department to meet the production needs of our clients. Standards are established for each team and used to measure progress. Any deviation from the quality control standards is observed, and steps are taken to correct the problem. Preventative maintenance follows to prevent these issues from arising again. By strictly adhering to ISO9001, ISO14000, QC080000, and ISO13485 compliance, Goodway guarantees that it meets the international standards of various industries.

Furthermore, our system is continuously reviewed and improved to identify and address any flaws in the manufacturing process. We implement the RJG scientific molding procedure to determine the optimal molding parameters for each of our tools during the development stage to avoid narrow molding windows. This method helps us control quality more effectively.

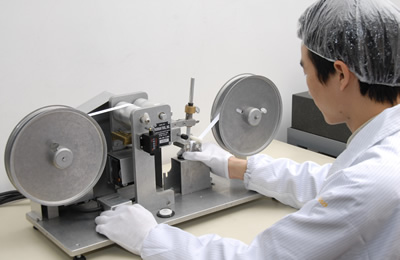

Having its own professional and experienced quality control team with a stringent set of procedures ensures the highest possible quality. Our quality control staff works closely with each department to meet the production needs of our clients. Standards are established for each team and used to measure progress. Any deviation from the quality control standards is observed, and steps are taken to correct the problem. Preventative maintenance follows to prevent these issues from arising again. By strictly adhering to ISO9001, ISO14000, QC080000, and ISO13485 compliance, Goodway guarantees that it meets the international standards of various industries.

Furthermore, our system is continuously reviewed and improved to identify and address any flaws in the manufacturing process. We implement the RJG scientific molding procedure to determine the optimal molding parameters for each of our tools during the development stage to avoid narrow molding windows. This method helps us control quality more effectively.